PRE-SEASON CHECKLIST

Tips to Prepare Your Seed Tender for Use

Updated: January 2025

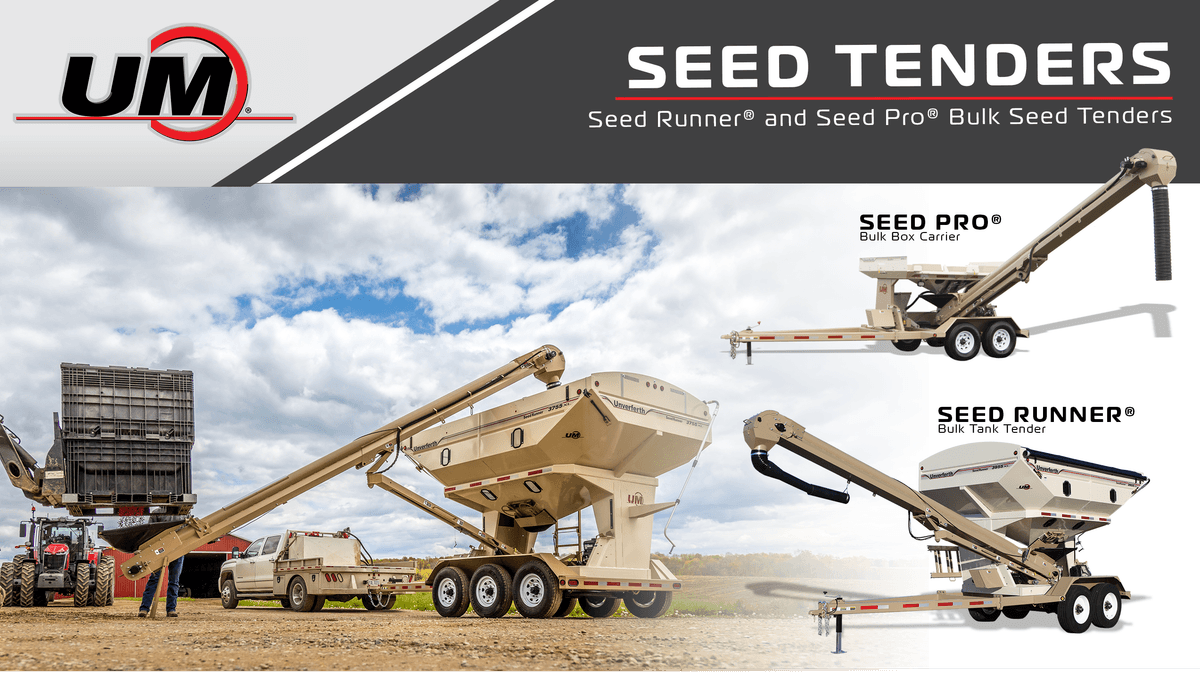

Preparing your Seed Tender by following the appropriate maintenance procedures ensures proper operation and maximizes the life of your equipment investment. Using the information below, you can rest easy knowing your Seed Tender is fully prepared for the upcoming use season. Below you will find valuable resources such as maintenance sections from operator’s manuals, a link to service parts, checks to perform before the initial use and moreEssential information about preseason prep for Seed Tenders.

Checklist

- Wireless Remote Battery Charging (if equipped)

- Charge the batteries for the wireless remote. The batteries can discharge during storage, so it is important to charge the batteries at least every 3-4 months and store them in temperatures above freezing.

- It is recommended to remove the batteries in the off season to prevent corrosion inside the wireless remote.

- Conveyor belt

- Check the conveyor belt tension. With access shield removed pull down gently in the center of the bottom side of the conveyor belt and the belt should deflect ½” (for 55- and 10-Series tenders). Increase the belt tension at the discharge end of the spout if the belt deflects more than ½”. Do not over-tension the belt.

- Check the conveyor belt alignment. Ensure the belt is running in the center of the pulley at the intake and discharge ends of the conveyor. Consult operators manual for the proper alignment procedure.

- Inspect the seals and brushes at the intake end of the conveyor. Replace if the seals show wear or allow the seed to fall to the bottom of the conveyor, or to the sides of the intake area.

- Wheels and Tires

- Check the tire pressure. Reference owners manual for your tire size.

- Check the wheel nut torque.

- Engine

- Fill the fuel tank with fresh gasoline if it was drained before storage.

- Check the engine oil level – change annually.

- Check the air filter. Clean or replace the filter if necessary.

- Review the engine owner’s manual for more details.

- Hydraulic Oil

- Let unit run for 10 minutes to warm the oil and operate and function to perform properly.

- Check the Hydraulic oil filter gauge and replace the hydraulic filter and oil if the gauge is in the red portion.

- Verify the hydraulic oil level in the reservoir is 1″ to 1.5” from the top of the sight gauge.

- Lubrication

- Grease the conveyor bearings and conveyor pivot points if not completed before storage.

- Lubricate the wheel bearings according to the seed tender owner’s manual.

- Battery Power Disconnect (2018 models & newer)

- Turn the battery disconnect switch on when ready to use the seed tender. Turn the switch off when the seed tender is not used for a long period of time.

View the original article and learn more about how to maintain your Seed Tender at;

Contact your local Parallel Ag dealer to learn more about what an Unverferth Seed Tender can do for your farm!

Call us at 1-800-659-1639 or visit our website at ParallelAg.com.