Farmers do not buy planters because of brochures or feature lists. They buy them because seed costs money, acres matter, and yield pays the bills. Every pass across the field has to protect potential, not quietly give it away.

That is exactly where the Fendt Momentum planter separates itself from the pack. Its performance is not based on theory or marketing claims. It has been proven through independent university research, multi year field trials, and side by side comparisons on real farms that deal with hills, swales, terraces, and changing soil conditions every day.

Momentum was not designed to look different sitting on a lot. It was built to fix yield losses that traditional planters have treated as unavoidable for decades.

Real Field Proof From Iowa Ground

One of the most talked about planter comparisons in the Midwest comes from Kelly Garrett with XtremeAg, farming highly variable ground in western Iowa. This was not a showcase demo or a carefully selected flat field. It was real terrain with elevation changes, side hills, and the kind of variability that exposes planter weaknesses fast.

The trial compared a Fendt Momentum planter directly against a John Deere 1770NT, both running the same agronomy practices in the same field. The difference showed up quickly. The Momentum produced a seven bushel per acre yield advantage, and that gap widened as terrain variability increased.

The biggest takeaway was not operator skill or adjustments. The advantage came from how the planter managed weight and maintained seed depth automatically as conditions changed. Garrett summed it up simply when he said the rougher the ground, the more difference the planter makes.

That kind of result changes expectations when it shows up on yield maps after harvest.

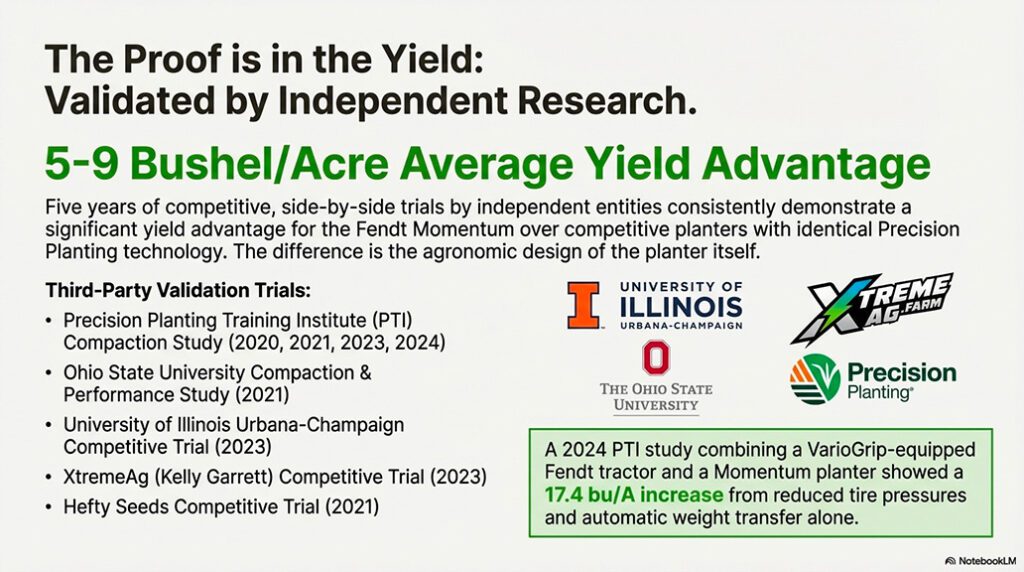

Independent Research That Confirms the Advantage

Momentum’s results did not stop with one farm. Multi year testing at the Precision Planting Training Institute from 2020 through 2023 looked closely at planter induced compaction and root zone damage. The trials compared Momentum against competitive planters using identical meters to isolate the impact of the planter itself.

Across locations and seasons, the Momentum delivered an average five bushel per acre yield advantage. Emergence was more uniform, root systems were healthier, and soil analysis confirmed reduced compaction in the seed zone. The key point is that population and operator behavior did not change. The yield gains came from how the planter managed its own weight across the toolbar.

That matters because compaction is one of the quietest yield thieves in corn and soybeans. It rarely shows up until late in the season, but when roots struggle, yield potential disappears fast.

Why Compaction Control Actually Pays

Most traditional planters treat compaction as part of the deal. Momentum was engineered around eliminating it. Its Load Logic weight management system continuously measures downforce at each row and redistributes load automatically. There are no manual adjustments and no lag time. The system reacts constantly as field conditions change.

Independent research has shown that reducing compaction alone can produce measurable yield gains even when everything else stays the same. That is not an incremental improvement. That is foundational return on investment.

University Data Backs Up Yield Consistency

Independent planter studies conducted by Ohio State University focused on seed placement accuracy, depth consistency, and emergence uniformity. Those trials showed yield advantages of up to nine bushels per acre along with more consistent emergence and improved population accuracy.

Even in trials where statistical thresholds were tight, the economic impact was clear. Consistent yield advantages in the 4 to 9 bushel per acre range add up quickly when multiplied across real acres.

Depth consistency is not flashy, but it is one of the strongest predictors of final yield. Momentum delivers that consistency across conditions where other planters struggle to react fast enough.

Eliminating Pinch Rows Means Recovering Acres

Conventional planters create pinch rows where transport wheels run behind row units and compact the seedbed. Momentum eliminates that problem completely. Its wheels follow existing tractor paths instead of running over planted rows.

Field observations and yield maps consistently show more uniform emergence across the entire toolbar width. Those rows are no longer sacrificed, and acres that used to underperform are brought back into production.

Where Momentum Separates the Fastest

Terrain is where Momentum really pulls away. Its 52 inch vertical contouring toolbar allows row units to follow ground changes far beyond what most planters can manage. In rolling Midwest fields, terraced Kansas ground, and swales across the Dakotas, side by side comparisons show yield advantages increasing as elevation change increases.

This is not about operator talent. It is about hydraulic engineering doing the work automatically while the planter stays focused on seed placement.

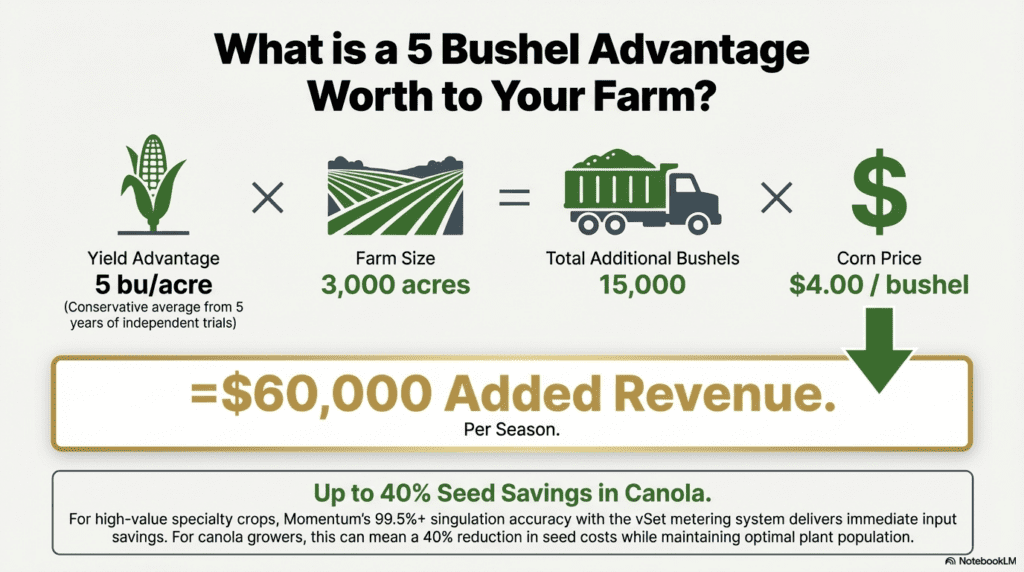

What the ROI Looks Like on Paper

When you put conservative numbers to the data, the math still works. On 2,000 acres of corn, a 3.9 bushel per acre advantage at four dollar and fifty cent corn produces more than $35,000 in additional revenue per year. At seven bushels per acre, that number climbs to over $63,000 annually.

Over a five year ownership window, that adds up to between $175,000 and $315,000 in added revenue, without factoring in long term soil health benefits.

Precision Also Reduces Waste

Momentum’s accuracy does not only show up in corn and soybeans. In canola trials, seed savings of up to forty percent were documented while maintaining or improving yield. That was driven by singulation accuracy approaching one hundred percent.

While canola is a specialty case, the takeaway applies across crops. Precision that reduces waste improves ROI no matter what you plant.

Built In, Not Bolted On

Other planters can add aftermarket meters or technology packages. They cannot replicate Momentum’s architecture. Its vertical contouring toolbar, automated weight management, integrated compaction control, and in line tandem wheel design are structural. They are not accessories.

That is why Momentum earned the 2025 Golden Ear Award for innovation and why its performance gains have held up across multiple seasons and independent studies.

Bottom Line for Midwest Farmers

Momentum does not rely on promises. It relies on data, case studies, and repeatable results in real fields. Independent research shows yield gains ranging from roughly four to nine bushels per acre. Compaction reduction is verified. Performance improves as terrain gets tougher. And the ROI pencils out fast.

If you farm variable ground and care about return on every equipment dollar, the question is not whether Momentum works. The data has already answered that.

The real question is how much yield is being left behind without it.