Features

Features may include:

AUTOMATIC SELF-ADJUSTING DECK PLATES

- An industry-first and revolutionary concept in yield capture technology.

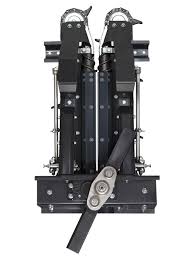

LONGER STALK ROLLERS

- The industry’s longest knife rollers combine with a smaller diameter for added plant processing time.

AGGRESSIVE OVERLAPPING CHAINS

- Drago gathering chains, which ride on oversized sprockets to reduce wear, are placed in front of knife rollers where overlapping chain fingers grab and capture stalks for processing. This feature is highly valued when harvesting downed corn.

“YIELD FIRST” CHOPPING DESIGN

- Features a rear-mounted chopping system that is unlike any other brand. The chopping system — placed well back on each row unit — allows ears to be harvested before the stalk is chopped.

BUILT-IN DURABILITY

- When you build a corn head for harvest efficiency, you also know the importance of a timely harvest. We know there is never a good time for a corn head not to perform, which is why Drago corn heads are engineered for harvest dependability.

INDEPENDENT ROW UNITS

- Deck plate gaps, both in-row and row-to-row, are determined by the size of stalks running through them, compared to hydraulic systems that set the same plate gap for every row unit.

ANGLED CHAIN DESIGN

- Gathering chains angle apart — front to back — to release stalks and avoid excessive trash from entering the combine.

POLY CHAIN GUIDES

- Each gathering chain has five poly chain guides that extend the life of the chain and are reversible after one side has worn.

OVERLAPPING GATHERING CHAINS

- Oversized idler sprockets, which reduce chain wear, are forward-placed, allowing overlapping chain fingers to grab and capture stalks for processing — a highly valued feature when harvesting downed corn.

SPRING-LOADED DECK PLATE PISTONS

- The spring-loaded deck plate piston design is simple and requires little maintenance.

AUTOMATIC SELF ADJUSTING DECK PLATES

- Understanding Automatic Self-Adjusting Deck Plates.

THE LONGER THE KNIFE ROLLER, THE BETTER.

- The industry’s longest knife rollers combine with a smaller diameter for added plant processing time. The extra time means roller tips can run slower, resulting in less ear bounce – less ear loss – without having to reduce combine speed. No other knife roller measures up to the performance of a Drago knife roller.

NOSE CONE BEARINGS

- Drago not only supports its knife rollers out front, but has two bearings and a grease bank built right into the nose cone itself. A dirt barrier is milled in to protect seals and bearings when tips are closer to the soil, as in down-corn situations.

KNIFE ROLLER SUPPORTS

- Drago builds bracket supports to keep knife rollers from spreading and breaking.

SLOWER TIP SPEED

- Having the longest knife roller with a smaller diameter reduces tip speed for less ear bounce, greater ear retention and reduced butt-shelling.

REDUCING EAR LOSS

- A knife-to-knife design pinches, pulls and opens up — allowing plants to move farther back into the corn head before the ear is removed.

LONGER STALK ROLLER

- Understanding Automatic Self-Adjusting Deck Plates.